After-sales commitment

Promise timely and efficient after-sales service, including maintenance, spare parts supply and troubleshooting, to ensure that customers' problems can be solved quickly.

Two-year free replacement for product quality problem | Free design service by professional design team | Lower than market price | Nanny after-sale service

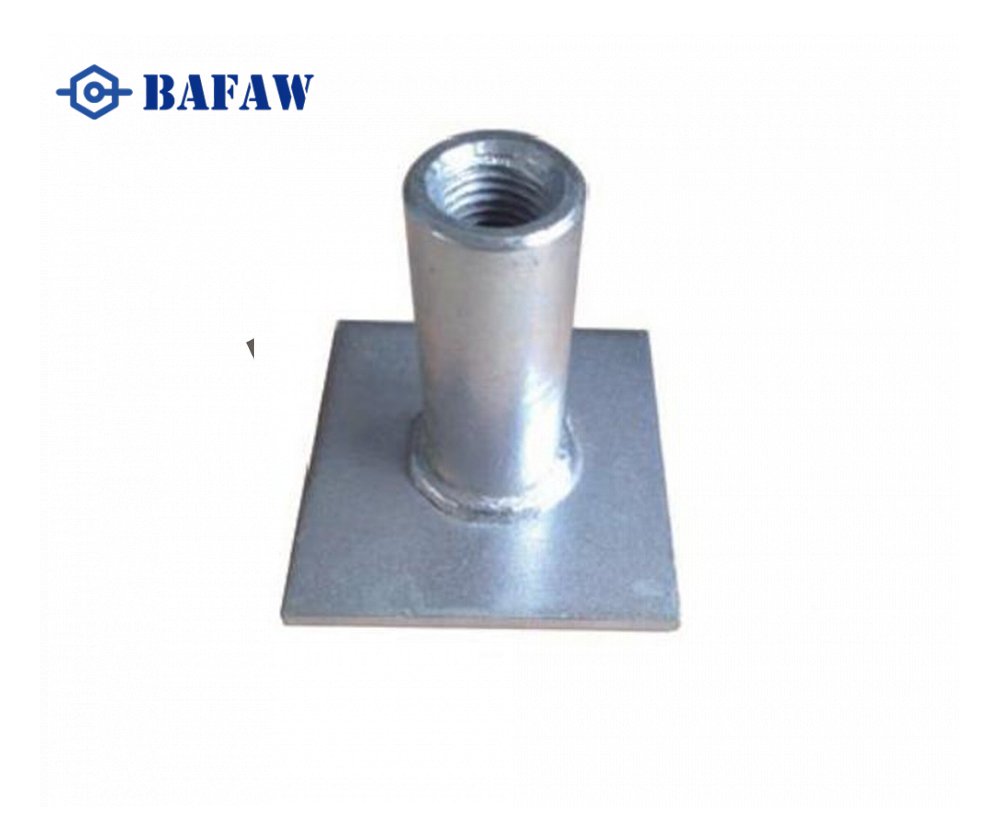

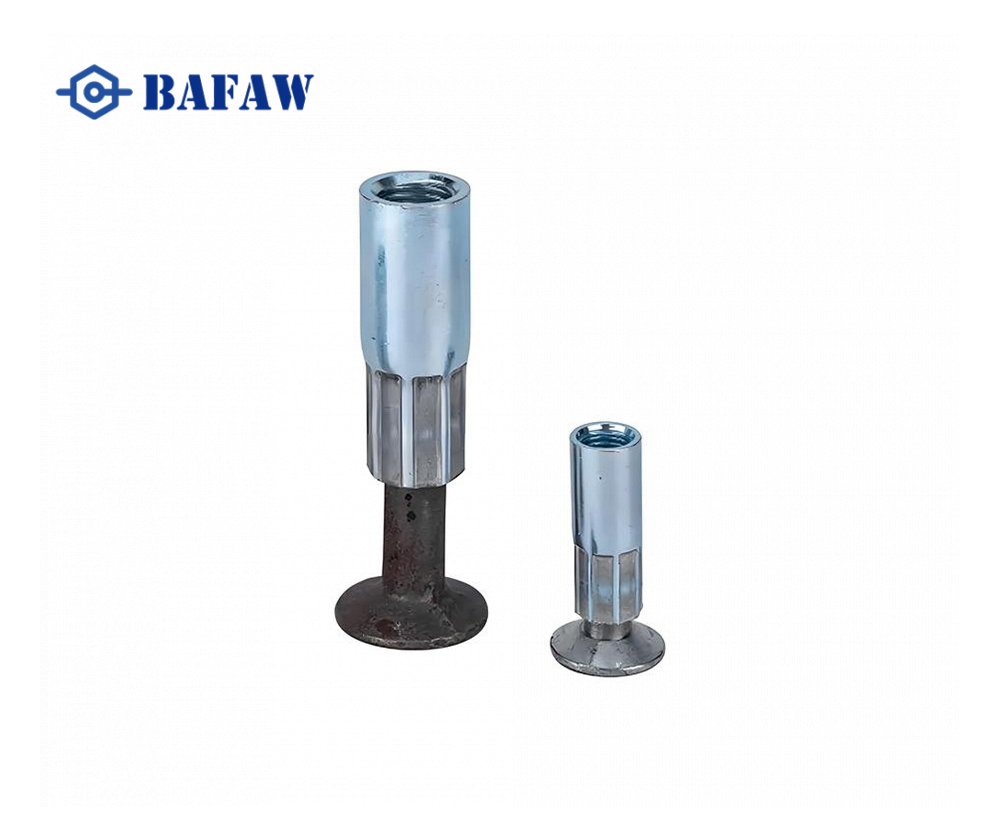

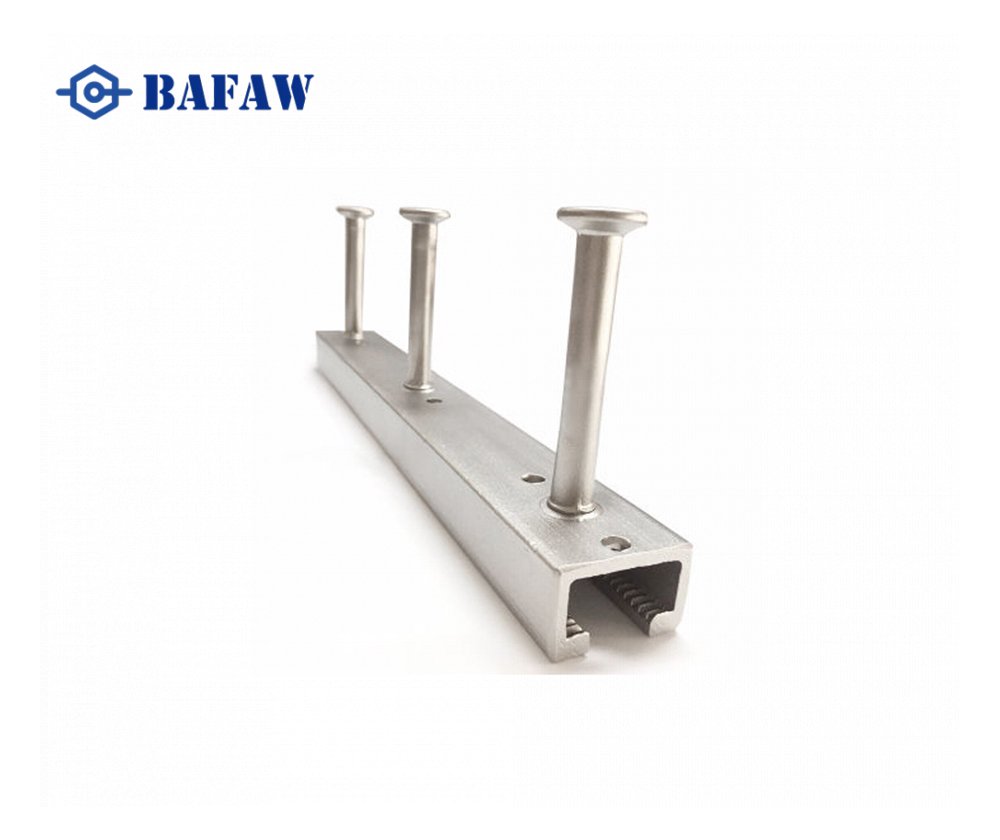

Customized parts are products or components that are specially designed and manufactured according to the customer's specific needs and technical specifications, with unique designs and a high degree of flexibility in terms of material selection, dimensional accuracy, shape complexity, and functional integration.

Often requiring high-precision machining and stringent quality control, these customized parts are used in a wide range of applications in manufacturing (e.g., specialized machine parts), construction (e.g., customized structural components), automotive (e.g., special engine components), and medical equipment (e.g., customized medical devices).e are also three coordinates, spectrometer, X-ray, etc. to ensure zero defects in the product.

By providing customized parts that are perfectly tailored to the needs of specific applications, companies can significantly improve productivity, product performance and market competitiveness.

Promise timely and efficient after-sales service, including maintenance, spare parts supply and troubleshooting, to ensure that customers' problems can be solved quickly.

Commitment to on-time delivery ensures that the customer's production or project schedule is not disrupted.

We offer competitive pricing and guarantee price transparency to help you reduce purchasing and maintenance costs while maintaining high quality standards.

Commitment to provide high-quality products that meet or exceed industry standards to ensure product reliability and durability. Valve products with quality problems within 2 years of free replacement

The manufacturing of custom parts involves a range of specialized processes tailored to meet specific requirements, including precision machining (turning, milling, drilling, grinding), casting (sand casting, precision casting, die casting), forging (hot and cold forging), welding (fusion and brazing), heat treatment (quenching, tempering, annealing), surface treatment (plating, coating, oxidation), and 3D printing (FDM, SLS).

These processes are selected based on the material, shape, size, precision, and application needs of the part, ensuring high-quality, tailored solutions for various industries.

We can design drawings and 3D drawings according to customers' requirements, and we can provide customized solutions based on our years of manufacturing experience, which can save you money while making higher quality products.

Likewise, we provide free samples.