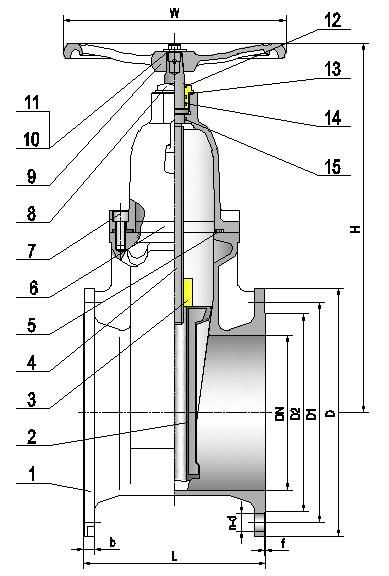

TECHNICAL REQUIREMENT :

Design and Manufacture Conform to EN1171,DIN3352,EN1074

Flange dimensions Conform to EN1092-2 PN16

Face to Face dimensions Conform to EN558-1 Series 14, DIN3202 F5

Testing Conform to EN12266, ISO5208

Driving mode: hand wheel, square Nut

Resilient Seated Gate Valve Medium: Water, Waste Water, Air, Oil

Resilient Seated Gate Valve Temperature: -20 to 120℃

Minimum 250μm epoxy coating inside and outside

The flap of resilient seated gate valve is encapsulated with rubber, using the elasticity of rubber to achieve a good sealing effect and good sealing.

Resilient seated butterfly valves, also known as “concentric” and “rubber seated,” are designed to handle liquid and gas applications demanding up to 400°F in heat or pressure up to 250 PSI. What makes the valve centric is the placement of all components centrally, with no offset in the body or stem packing adjustment. The valve disc operates with a 360º rotation around the center axis, achieving a seal through the interference fit between the disc and the rubber seat at the stem and along the disc edge.

Unlike offset seated butterfly valves, the rubber seat ensures that the valve body does not come in contact with the material passing through the pipe. This maintains the purity of the production contents and allows for the use of less expensive body materials. However, depending on operational conditions, the rubber may wear out, affecting the sealing function.

And every valve is tested for penetration according to the requirements. Meanwhile, the design of the concealed stem solves the problems of leakage and rust common in other gate valves.

DIN3352 F5 is commonly used in the fields of city water supply, industrial pipeline oil transmission, gas transmission, chemical industry, steam, agricultural irrigation, etc. It has the features of simple structure, stable performance and good sealing.

The thickness of internal and external epoxy coating is not less than 250μm, which is more excellent for rust prevention in sewage system.

VALVE WARRANTY 2 YEARS, UNCONDITIONAL REPLACEMENT FOR QUALITY PROBLEMS.