After-sales commitment

Promise timely and efficient after-sales service, including maintenance, spare parts supply and troubleshooting, to ensure that customers' problems can be solved quickly.

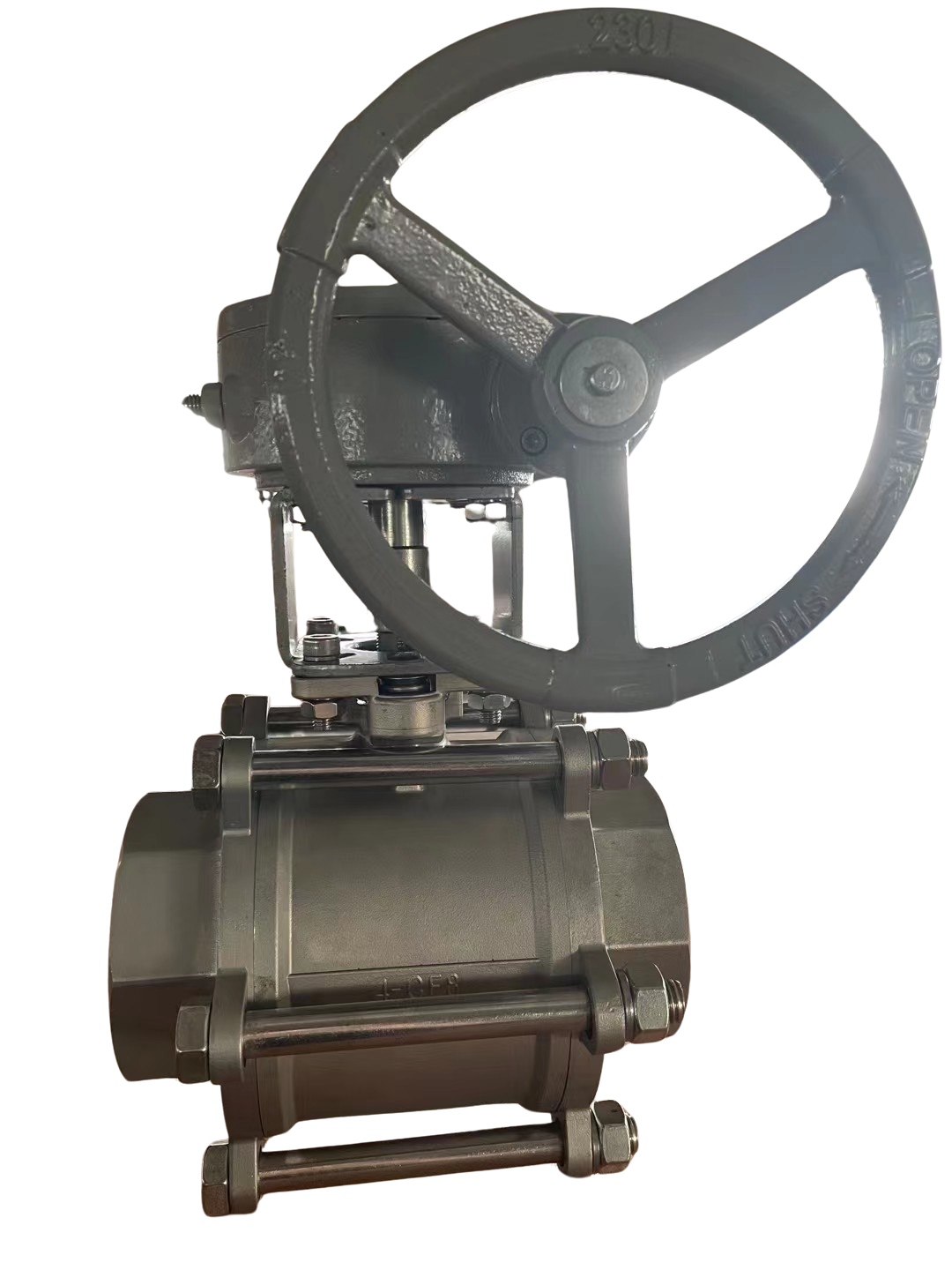

We offer various customized valve solutions for the oil, gas, and chemical industries. Actuation options include:

Manual, Electric, Pneumatic, Hydraulic, Electro-Hydraulic, and Pneumatic-Hydraulic.

Our products have been certified by: API6D,API609,API607&API6FA,SIL3,ATEX,CE,ISO9001,ISO14001,ISO15848-1,TS&CU-TR 0101032/012.

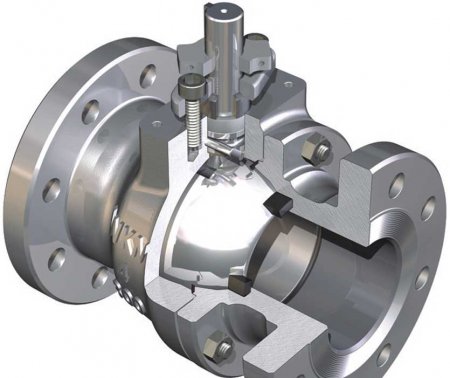

Our industrial ball valves aren’t just “valves”—they’re your system’s silent guardian.

From power plants to offshore platforms, our valves ensure zero leaks, longer service life, and reduced maintenance costs.

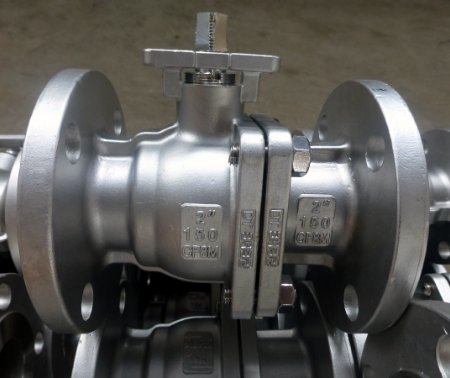

✔ Designed for corrosive media, steam, high temp & pressure

✔ 100% tested under API 598 standards

✔ Available in stainless, WCB, duplex steel & custom alloys

→ Want to match the right valve to your project? Let’s talk.

Promise timely and efficient after-sales service, including maintenance, spare parts supply and troubleshooting, to ensure that customers' problems can be solved quickly.

Commitment to on-time delivery ensures that the customer's production or project schedule is not disrupted.

We offer competitive pricing and guarantee price transparency to help you reduce purchasing and maintenance costs while maintaining high quality standards.

Commitment to provide high-quality products that meet or exceed industry standards to ensure product reliability and durability. Valve products with quality problems within 2 years of free replacement

- Blowout-proof stem & fire-safe design (per API 607)

- Anti-static device & ISO 5211 mounting pad

- Full port / reduced port options

- Seat materials: PTFE, RPTFE, Devlon, PEEK

- Surface treatments: Nickel-plated, ENP, Nitriding

→ Need CAD drawings or material traceability? Contact us.

Facing issues like frequent leakage, stuck operation, or corrosion in your current valve setup?

We solve this by:

- Using precision-machined ball & stem interfaces for smoother operation

- Providing superior sealing seats that resist wear, heat, and chemicals

- Ensuring every valve is pressure-tested before delivery

The result?

- Longer uptime

- Safer systems

- Less maintenance cost