Ball valves are a critical component in controlling the flow of water, steam, oil and gas. They are often used in non-industrial residential applications as well. Due to their ease of use, quick operation, and durable construction, ball valves have become a mainstay in countless systems.

Like any tool, they have strengths and weaknesses. In this section, we’ll discuss the strengths and weaknesses of ball valves. It is a look at what they don’t do, and how they fit into multiple workflow.

The Upside of Ball Valves

A major strength of ball valves is their fast on-off control. You only have to turn them a quarter turn, 90 degrees, to fully open or close them. This design makes for much quicker action than gate valves, which need multiple turns.

This rapid response is ideal for applications that need immediate shut-off. It performs particularly well in emergency shut-off applications and to systems that are often cycled. Ball valves provide a complete seal as well, preventing leakage—which is critical for applications such as gas lines or chemical factories.

Their simplistic design, featuring a round ball and full bore (opening), allows for fluid to pass through with minimal resistance. In most applications, this leads to lower pressure drop. However, in cases where it is only partially open, a ball valve can cause turbulence and a more erratic flow.

Ball valves are able to manage high pressure and high flow, remaining leak free for decades if properly maintained. Three-piece designs allow for easy user replacement of seats and seals. This design removes the need to pull the valve completely out, meaning less downtime.

These valves work great in industries like waterworks, food and beverage, and gas plants. Where they really excel is when the pipe size is less than 2 inches.

Possible Ball Valve Problems

This does not mean that ball valves are without their flaws. When the seat wears out—usually due to grit or aggressive chemicals—the seal is lost, and leaks can occur. Adding to these problems is the fact that poor maintenance or use of the inappropriate valve for the application can exacerbate these problems.

Quicker flow adjustments Ball valves do not perform well on pipe sizes over 2 inches and where flow must be throttled. Their spherical design naturally causes turbulence and excessive pressure drop if they are not fully open.

They cost more initially, largely in three-piece types, which may not allow for small budgets. Additionally, users need to be on the lookout for leaks and seat wear, because a malfunctioning valve can both delay jobs or even pose safety hazards.

Best Applications for Each Valve

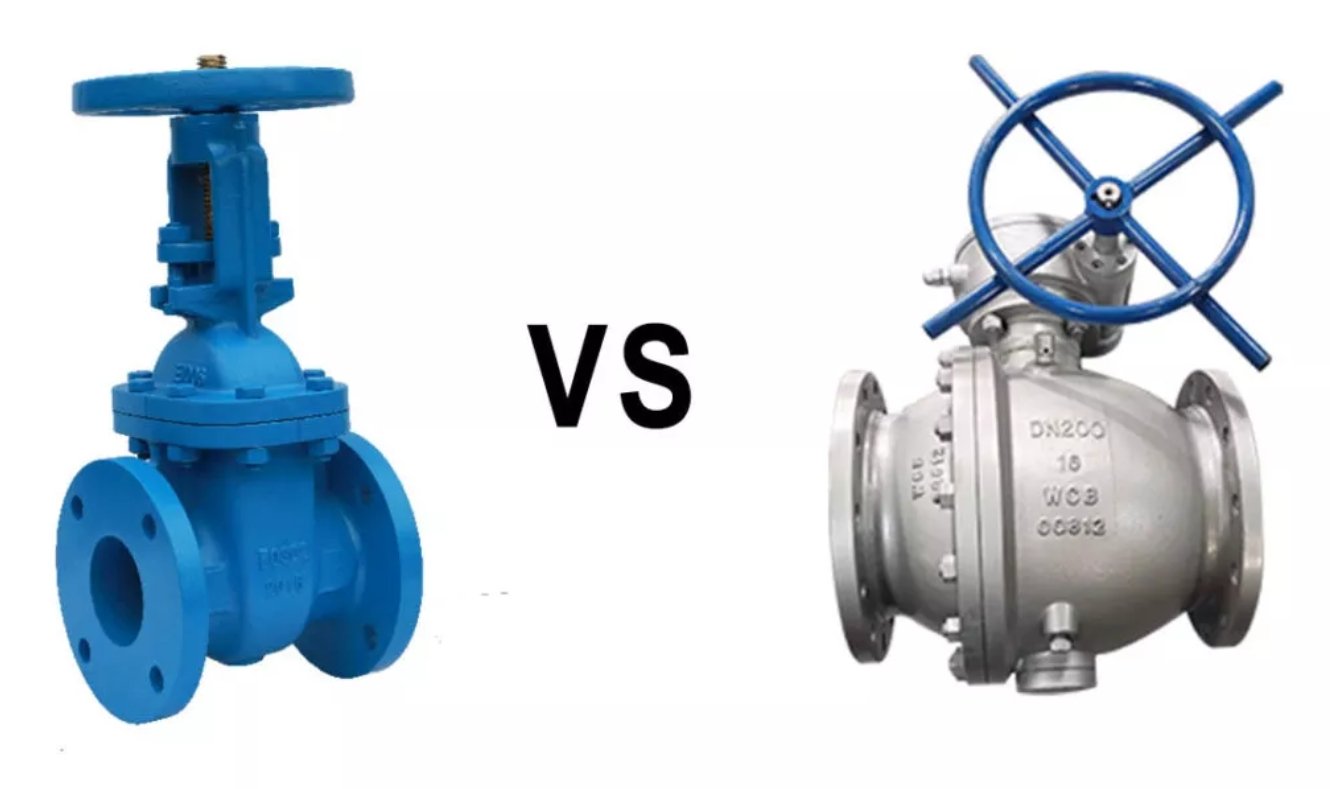

Deciding between gate and ball valves largely depends on their ideal application in real-life field tasks. Understanding what each valve does and where it fits in the field is essential. Its location is up to flow requirements, pipe diameter, and how often you want to open and close the valve.

Selecting the proper valve ensures safer systems, saves costs, and reduces downtime. Here’s where each valve excels, with stats on why these selections are important.

Ideal Jobs for Gate Valves

Gate valves are most effective in applications where you need a valve that is either fully open or fully closed. These valves do well in water supply lines, irrigation, fire protection, and sewage systems. They are most effective in applications with larger pipes, usually two inches or larger.

That’s because their construct makes transmissions water and other fluids to flow directly through with little resistance. You’ll find them in municipal water mains, wastewater treatment plants, and legacy plumbing systems in large commercial and institutional buildings. They suit situations where a line is normally left open.

Ideally, you’d use them only when you know you need to shut down for repairs or in an emergency.

Where Ball Valves Really Shine

Compared to gate valves, ball valves are more effective at quickly shutting off, providing a tight seal, and enduring high pressure. Today, you can find them in gas lines, water treatment, chemical plants, and HVAC systems.

Their low-torque action and design make them perfect for jobs needing quick stops, like emergency shut-offs or automated process lines. Durability and leak-proof seals are essential in newer plumbing applications and ball valves work great for this as well.

They are made in three or four port versions, making them ideal for mixing or splitting flows.

Common Uses in US Homes/Industry

Ball valves are typically found shut-off main lines, sinks and outside spigots. In addition to their simple operation, they seal extremely well. Gate valves are more commonly found in plumbing of older homes, or in large municipal water supply lines.

In industry, both types exist, but the application is based on flow requirements and safety considerations. Process control systems and gas distribution systems are typical applications for ball valves.

Gate valves are perfect for controlling big water lines and waste systems. Choosing the proper valve prevents damage to plumbing, prevents leaks, and allows systems to operate efficiently.

Choosing the Right Valve for You

Selecting between gate and ball valves depends on your system’s needs, the kind of fluid, and how often you use the valve. Choosing the right valve for your specific application can save you years of reliable performance and reduce maintenance costs.

The right one for you is determined by your flow, pressure and budget requirements. Here’s a quick look at the main things to check:

Flow rate and control needs

How often the valve will be operated

Pressure and temperature demands

Installation requirements and costs

Maintenance needs over time

Match the Valve to Flow Needs

If you need high flow and fast shut-off, ball valves do best. Their 90° quarter turn saves time by letting you open/close the line in just seconds. This feature is particularly useful for water supply lines and air lines.

Gate valves have a slow rise stem that provides more precise adjustments for throttling flow. If you require to divide streams or reverse circulation, multi-port ball valves are the choice. Match the valve to flow needs. Fast on and off control for a ball valve vs. Slow, gradual control with a gate valve.

Consider How Often You'll Use It

If you need to cycle the valve dozens of times a day, a ball valve’s design resists wear over time. Its seats and seals are easy to replace on three-piece models, making their fix simple.

Gate valves are great for locations where you only need to open and close them once in a while. Their design can get stuck if you actuate them too often.

Check Pressure and Temperature Needs

Each valve is rated for a specific pressure and temperature. Ball valves, due to their quarter-turn pattern and tight seal, are known to resist leaks even in extreme conditions.

For steam or high-pressure lines, always verify the specifications to prevent premature wear. Work that is pressure-sensitive, such as chemical lines, requires the right valve rating to maintain safety.

Installation Ease and Budget Impact

Ball valves, particularly three-piece, are more expensive initially but allow easier repair and maintenance. Gate valves may be less expensive but more difficult to repair on site.

Consider the installation cost as well as potential future repair expenses.

Think About Long-Term Maintenance

Consider long-term maintenance. Ball valves require less attention in the long run, particularly when you choose three-piece models.

Gate valves, for instance, can become stuck or leak over time if not regularly tested. Whatever valve you choose, plan to inspect seals and seats periodically.

Conclusion

To choose between gate valves and ball valves, consider your application requirements. Gate valves provide excellent flow control and are ideal for use in larger diameter pipes. Ball valves open and shut quickly, require minimal exertion, and maintain high pressure without leaking. Think about what you want: steady flow, easy shutoff, or less upkeep. For residential water lines, ball valves usually prevail for quickness and water-tightness. For large diameter water mains or locations where flow control capability is essential, gate valves are the ideal solution. There isn’t one valve that’s right for all applications. Each type has one thing they do the best. To read more about how to choose the correct valve, head over to home improvement discussion boards. You can get matched with an expert to help you weigh your options.

FAQ

What is the main difference between a gate valve and a ball valve?

A gate valve uses a sliding gate to stop or start flow, while a ball valve, particularly the brass ball valves, utilizes a rotating ball with a hole. Ball valves are quicker to turn on and off, making them a useful type in plumbing systems.

Which valve is better for quick shut-off?

Which valve is more suitable for quick shut-off? Their quarter-turn design allows for quicker and more efficient operation than gate valves.

Are gate valves or ball valves more durable in the long run?

Ball valves, such as brass ball valves and PVC ball valves, tend to have a longer lifespan due to their simple design, which creates a tight seal and minimizes leaks.

Can both valve types handle high pressure?

So, can both valve types handle high pressure? Ball valves, especially brass ball valves, shine under these conditions and are incredibly unlikely to fail.

Which valve is more suitable for residential plumbing in the U.S.?

Which valve is better for residential plumbing in the U.S.? According to Richmond, brass ball valves provide positive shut-off, easy operation, and reduced chance of leakage in the plumbing system.

Are gate valves or ball valves easier to repair?

Ball valves, such as brass ball valves, tend to be easier to repair or replace compared to gate valves, which have increased moving parts.

Do ball valves or gate valves handle dirty water better?

Do ball valves, like brass ball valves, or gate valves handle dirty water better? Gate valves are likely to become clogged or stuck if debris is present.