After-sales commitment

Promise timely and efficient after-sales service, including maintenance, spare parts supply and troubleshooting, to ensure that customers' problems can be solved quickly.

Two-year free replacement for product quality problem | Free design service by professional design team | Lower than market price | Nanny after-sale service

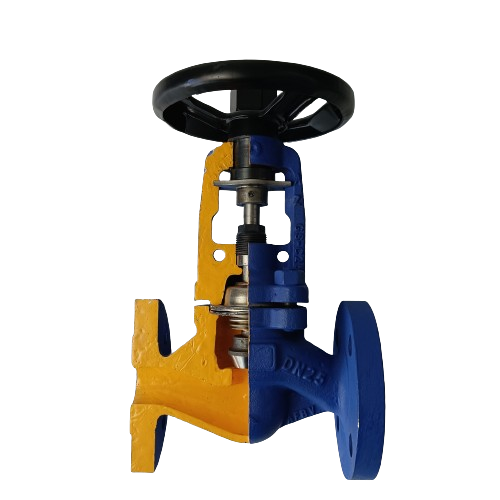

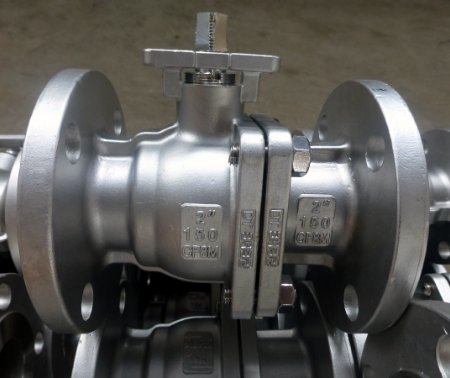

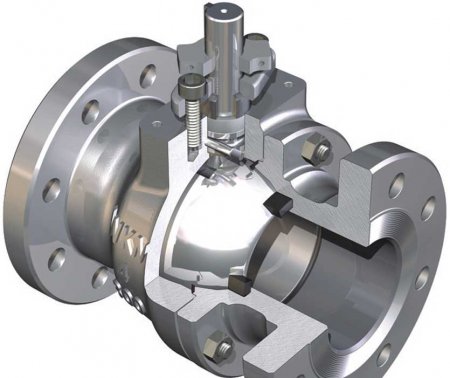

Industrial valves are key devices used to control and regulate the flow of fluids (including liquids, gases and slurries) and are widely used in many industrial fields such as petroleum, natural gas, chemical industry, electric power, metallurgy, pharmaceuticals and food processing. Its main functions include opening and closing pipes, regulating flow, controlling flow direction, regulating and controlling system pressure, and preventing backflow. According to the different functions and structures, industrial valves can be divided into the following categories: Gate Valve, Ball Valve, Butterfly Valve, Globe Valve, Check Valve, Safety Valve, Control Valve.

When selecting industrial valves, it is necessary to comprehensively consider the characteristics of the medium (e.g., corrosivity, Viscosity, solid content, etc.), operating conditions (such as temperature, pressure, flow, etc.), valve material, connection and operation (manual, pneumatic, electric, etc.). Correct selection and maintenance can significantly improve the safety, reliability and operational efficiency of the system.

Promise timely and efficient after-sales service, including maintenance, spare parts supply and troubleshooting, to ensure that customers' problems can be solved quickly.

Commitment to on-time delivery ensures that the customer's production or project schedule is not disrupted.

We offer competitive pricing and guarantee price transparency to help you reduce purchasing and maintenance costs while maintaining high quality standards.

Commitment to provide high-quality products that meet or exceed industry standards to ensure product reliability and durability. Valve products with quality problems within 2 years of free replacement

When purchasing industrial valves, it is crucial to consider the medium characteristics (type, corrosiveness, viscosity), operating conditions (pressure, temperature, flow rate), and the appropriate valve type (functional requirements, operation mode). Material selection (body and sealing materials), connection type (flange, threaded, welded), adherence to standards and certifications, and the reputation and capacity of the manufacturer are also essential.

Additionally, evaluate the cost-effectiveness, including long-term operational and maintenance costs, after-sales service, and delivery time to ensure the valve meets the specific application requirements and delivers optimal performance.

At BAFAW, valves are subjected to secondary testing and are equipped with an independent testing laboratory. All valves are subjected to penetration testing to avoid undetectable defects and to prolong the service life of the valves.

Our valves after two quality control and penetration testing, to great extent to eliminate the appearance of imperfections that can not be detected, greatly extending the service life of the valve, and our valves support the unconditional replacement of the quality of the 2-year problem, you do not have to worry too much about the purchase of valves in Bafaw!